Condition:

New

Machine Type:

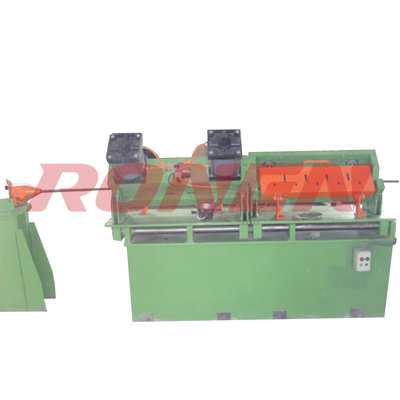

Induction Heating Machine

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

2 years

Core Components:

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump, IGBT

Warranty:

1 Year

Key Selling Points:

High-accuracy

Applicable Industries:

Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works , Energy & Mining

Showroom Location:

Nigeria, Japan, Turkey, Philippines, Indonesia, Pakistan, India, Thailand

After-sales Service Provided:

Engineers available to service machinery overseas, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Power:

10-10000kW

Frequency:

0.1kHz-20000kHz

Application:

annealing,quenching,melting,welding

Daimeter:

9.53

Material:

steel, stainless steel, aluminum, copper, titanium

Type:

Fully Automatic

Voltage:

three phase 220-660V, 50-60HZ

Usage:

Used to build buildings with large loads

Factory:

Yes

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Japan, Ukraine, Nigeria, Turkey, United States, Philippines, Indonesia, Pakistan, India, Thailand

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!